RHeX® Rotating Heat Exchanger with enhanced performance

The natural evolution of the winning RCR design: How to turn an acclaimed winner into an even better performer

With more than 5,000 units sold worldwide, the RCR rotating

heat exchanger has gained a "de facto” status as best practice to recover heat from very polluted streams. Time passes and technology advances, thus, after 25 years of undisputed success, we completely re-invented the best heat recovery unit on the market.

For more info and a view on possible applications visit our dedicated web site

www.pozzienergy.it

TECHNOLOGY TOWARDS LOWER MAINTENANCE

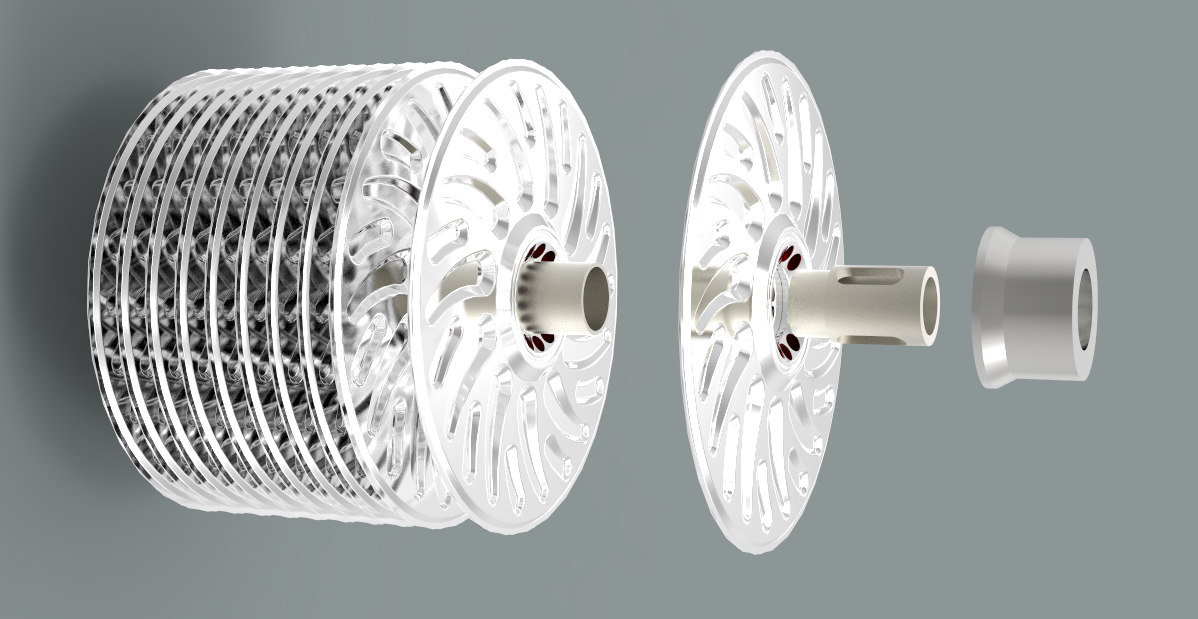

A painstaking computer-simulation engineering effort led to the development of what will be the next standard self-cleaning exchanger. The new design has been granted an International Patent in 2013 and it is ready for the market.

Accurate finite-elements analysis has allowed a dramatic improvement of the structural rigidity and the pressure resistance of the disks, while the novel teardrop shape of the reinforcing dimples has proven to enhance the dynamic flow pattern of the fluid in the exchanger.

TECHNOLOGY TOWARDS HIGHER EFFICIENCY

Particle-motion and thermal analysis have refined the exchanger physical details to improve heat transfer while minimizing boundary layer conditions and increasing the dynamic shear stresses near the surfaces to enhance the self-cleaning action of rotation.

Lenticular shells are no more welded one to the other: the new design makes them modular units which can be mounted freely on the supporting shaft. They can be, thus, removed and interchanged.

The new patented blade design of the disk dimples

allows for a positive "pushing” action on the effluent, making the unit even more suitable for thick and heavy fluids, further reducing the generated pressure loss.

The reticular structure of the dimples and their new welding technique creates a much more pressure resistant disk: with a bursting pressure of 36 bar, it safely allows for a rated inner pressure of 5 bar.

The reduced disk pitch increases the compactness of the exchanging unit, making it possible to significantly increase heat transfer in the same footprint of the original RCR design.

The better fluid-dynamic control of the generated turbulence allows for higher rotational speed of the exchanging surfaces, thus increasing the self-cleaning, anti-fouling action of the rotating exchanger.

|

The RHeX project has received funding by the European Union’s Horizon

2020 Research and Innovation Program under Grant Agreement n° 723930. |

|

RHeX is part of the LowUP project: Low

valued energy sources UPgrading for buildings and industry uses http://lowup-h2020.eu/ |